Pipe Conveyor Roller Idlers

Pipe roller conveyor idlers outer diameter is selected based on conveyor carrying capacity Tons per hour and corresponding belt width used.

Conveyor rollers standard pipe diameters MM of 76, 89, 101, 114, 127, 139, 152, 159, 165 mm sizes manufactured out of steel tube Class C, B, A of different thicknesses.

Idler diameter of 76, 89 mm sizes are used for conveyor-belt width up to 500 mm breadth belting

Idler diameter of 89, 114 mm sizes are used for conveyor-belt width up to 750 mm breadth belting

Idler diameter of 114, 139 mm sizes are used for conveyor-belt width up to 1000 mm breadth belting

Idler diameter of 139, 152 mm sizes are used for conveyor-belt width up to 1200 mm breadth belting

Idler diameter of 152,165, 195 mm sizes are used for conveyor-belt width 1400 mm and above belt width

Impact roller conveyor rubber-rings or discs of 32 or 50 mm thick diameter OD sizes MM of 114, 140, 165, 190 with idler shell size of 76, 89, 114, 139 mm respectively used at loading point.

However, idlers diameter selection has to be made on overall conveyor-system design calculating various other load and operational speed factors as well.

Idlers manufacturing in other diameter size also undertaken provided quantities are substantial, as pipe have to be drawn out that may take 4 weeks extra more delivery time than regular sizes.

Pipe conveyor-idlers also manufactured as per Drawings specifications.

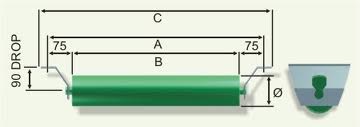

Roller Length of HIC Conveyor Idlers Manufactured

Single roll flat carry idler produced for conveyor-belt width MM of 500, 600, 650, 800, 1000, 1200, 1400, 1600, 1800, 2000 mm BW in idler shell length MM of 600, 700, 750, 950, 1150, 1400, 1600, 1800, 2000, 2200 mm L long roller length respectively.

3 roll off set trough idler shell length MM of 200, 235, 250, 315, 380, 465, 530, 600, 670, 750 mm L for belting width MM of 500, 600, 650, 800, 1000, 1200,1400, 1600, 1800, 2000 mm BW.

Conveyor carrying roller with frame also produced made out of quality MS Angle, Flat and Channel.

Single roll flat return idler length MM of 600, 700, 750, 950, 1150, 1400, 1600, 1800, 2000, 2200 mm for conveyor-belting width as stated.

Rubber disc return idlers length as stated for reliable conveying ensuring tight package in the outer areas of conveyors rubber-belt.

Return idlers with rubber lagging of 5mm or 10mm thickness in length as desired, functions as a counter idler for belt cleaner.

Idler rollers in non-standard sizes also produced.

Bearing Size And Shaft Diameter of HIC Idlers Produced

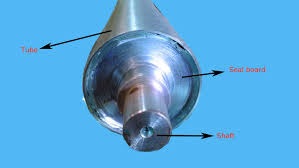

Bearing sizes in idlers of 6204zz, 6205, 6206 or 6306, 6207, 6208 or 6308 seize resistant type respectively of reputed company SKF or FAG or equivalent as per EN8 steel spindle diameter or shaft thickness 20, 25, 30, 35, 40 MM used in conveyor-idler with nylon bushing sealed to prevent dust.

Idler shaft diameter sizes MM of 20, 25, 30, 35, 40 mm steel spindle selected based on bearing life-time calculated on basis of idler load and idler speed.

Notching dimensions on idler spindle for 20mm, 25, 30, 40mm of 9 x 14 mm, 12 x 18, 12 x22, 12 x 32 mm sizes respectively are kept as standard shaft end dimensions for roller idlers. Idlers shaft end dimensions any specific, needs to be stated while rollers idlers ordering.

Sealing System in Idler Rollers Made by HIC Conveyor

Brilliant sealing system to keep idler rollers fully dust protected that are packed with high lithium grease having 0.025 friction factor multi-labyrinth type nyloplast seals with moulded dust cover or adopter and back seal cup to prevent from rain-water.

Surface Treatment on HIC Conveyor Rollers Applied

Primer paint as standard finishing on idler rollers, good resistant to corrosion, wear and sticking.

Epoxy coating on idlers as surface treatment also carried used in conveyor-installations demanding much higher resistance to corrosion and excess wear than primer like monsoon areas, dusty locations.

Rubber coating on idlers that are excellent corrosion resistant, wear resistant, chemicals resistant, sticking resistant thereby increasing life span of conveyors rollers giving trouble-free performance.

Quantity of HIC Conveyor Rollers Supplied

Conveyor rollers Minimum order quantity of 50 numbers in one lot.

Packed in sea-worthy jute or HDPE bags. Also, packed in wooden cases on specific orders.

HIC Conveyor Drive Rubber Manufacturers India

HIC Conveyor Drive Rubber Manufacturers India